The global injection molding market has experienced significant growth in recent years, driven by the increasing demand for precision parts across various industries including automotive, consumer goods, and electronics. According to a report by Grand View Research, the injection molding market was valued at approximately $250 billion in 2021 and is projected to expand at a compound annual growth rate (CAGR) of 5.6% from 2022 to 2030. In this competitive landscape, the importance of high-quality injection mold makers cannot be overstated, as they play a critical role in ensuring the reliability and efficiency of the manufacturing process. Selecting the right injection mold makers is essential for businesses looking to optimize production and reduce costs, making it crucial to know the top players in this field. This article will explore five of the best injection mold makers that stand out for their innovation, quality, and expertise, providing insights that are vital for manufacturers seeking to enhance their operations.

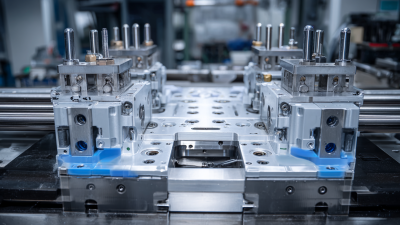

When it comes to high-quality production, selecting the right injection mold maker is crucial for ensuring precision and efficiency in the manufacturing process. The top five leaders in the industry have established themselves through a combination of advanced technology, skilled craftsmanship, and a commitment to customer satisfaction. These companies not only have a robust portfolio of successful projects but also emphasize innovation, enabling them to stay ahead in a competitive landscape.

Among these industry leaders, companies consistently integrate cutting-edge materials and techniques into their molds. They focus on creating tailor-made solutions that meet specific client needs, whether for automotive, consumer goods, or medical applications. Their reputation for reliability and ability to deliver complex molds has earned them loyal partnerships across various sectors. By continually investing in research and development, these injection mold makers are not just meeting today’s standards but are also shaping the future of manufacturing.

Injection mold manufacturing is a complex process influenced by several key factors that can determine the success of a project. Among these, material selection plays a crucial role. According to the 2022 Global Injection Molding Market Analysis Report, more than 70% of manufacturers consider the choice of materials as pivotal in achieving desired product properties and cost-effectiveness. Selecting the right polymer not only impacts the durability and functionality of the final product but also affects production efficiency, with some materials offering faster cycle times than others.

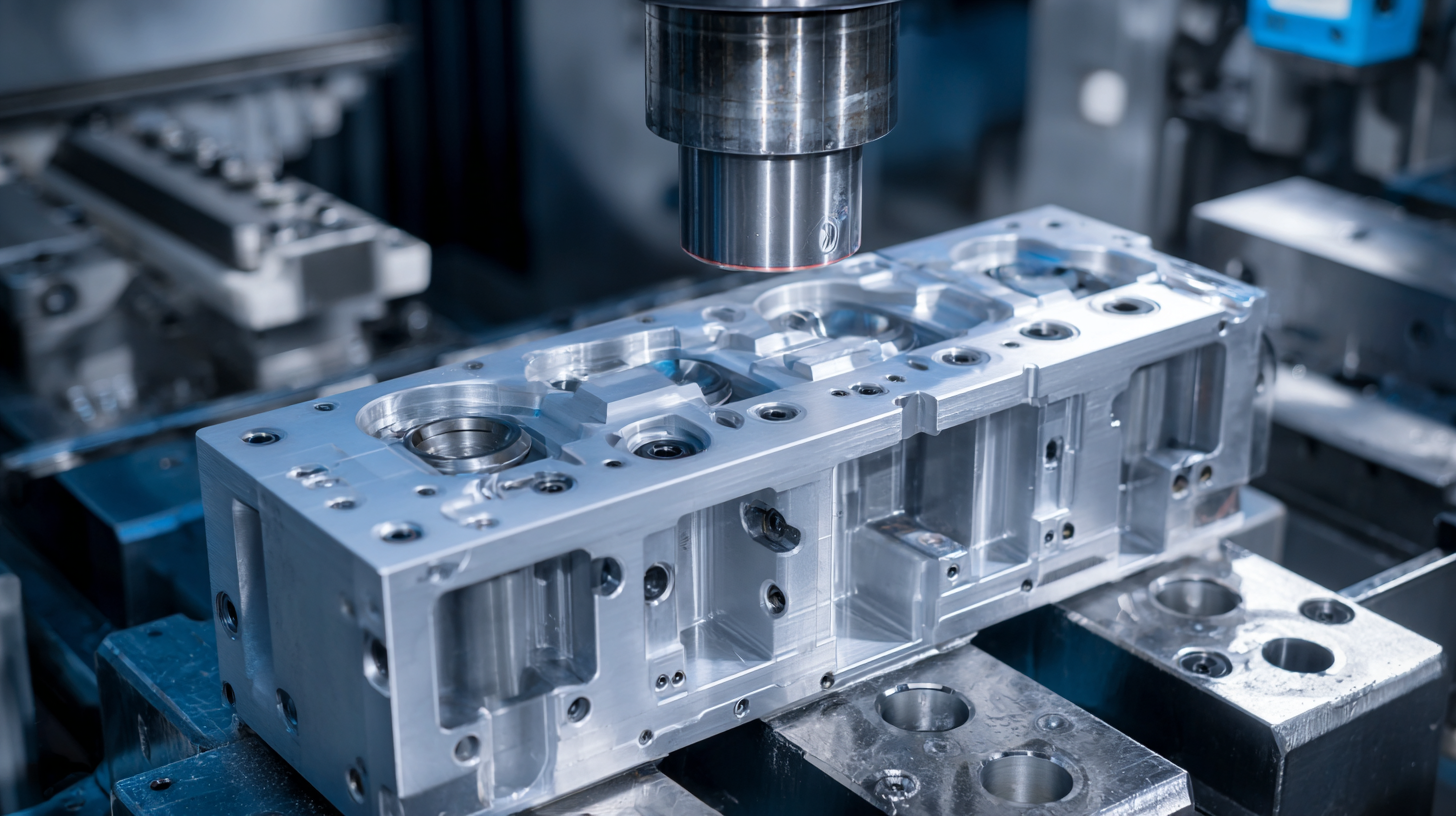

In addition to material selection, the design and precision of mold tooling are critical. Industry reports indicate that 60% of production issues stem from inadequate tooling design, underscoring the need for expertise in mold making. The implementation of advanced technologies, such as computer-aided design (CAD) and simulation software, has significantly enhanced the accuracy and reliability of molds, reducing the likelihood of defects and ensuring a smooth manufacturing process. Companies that invest in these technologies often see a 20% decrease in time-to-market, demonstrating the tangible benefits of modernized injection mold manufacturing practices.

When considering injection mold making, understanding the associated costs is crucial for businesses aiming to maximize efficiency and budget. The costs can vary significantly based on several factors, including the complexity of the mold design, the materials used, and the manufacturing techniques employed. For instance, high-precision molds designed for intricate components will require advanced technologies and skilled labor, leading to higher costs compared to simpler molds.

Moreover, the choice of injection mold maker can impact pricing. Established manufacturers with a track record of quality may charge a premium for their services, reflecting their expertise and the use of advanced machinery. It’s essential to conduct a comparative analysis of various mold makers, assessing not only their pricing but also the quality of their work and their ability to meet project timelines. This comprehensive understanding will help businesses make informed decisions and possibly negotiate better terms, ensuring that they receive value for their investment in injection molding.

The injection molding industry has been witnessing rapid technological advancements that are shaping the future of manufacturing. One of the most significant trends is the rise of smart manufacturing technologies, which incorporate IoT (Internet of Things) and machine learning. Manufacturers use sensors and data analytics to monitor production processes in real-time, optimizing efficiency and reducing downtime. This connectivity not only enhances productivity but also enables predictive maintenance, allowing for timely interventions before breakdowns occur.

Another critical innovation is the development of new materials and sustainable practices. As environmental concerns grow, injection mold makers are increasingly adopting biodegradable plastics and recycling methods. These materials not only meet consumer demand for sustainability but also open new avenues for product design. Additionally, advancements in 3D printing technology are enabling more complex geometries in mold design, reducing lead times and costs associated with traditional methods. Overall, these technological innovations are driving the injection molding industry towards greater efficiency and sustainability, setting the stage for a more dynamic manufacturing landscape.

When assessing the top injection mold makers, it's crucial to examine successful projects that highlight their capabilities and innovation. For instance, one leading manufacturer recently partnered with a medical device company to produce precision molds for a new surgical instrument. The project showcased the manufacturer’s expertise in creating complex geometries and maintaining strict tolerances, which are vital in the healthcare sector. This collaboration not only streamlined production but also resulted in significant cost savings for the client.

Tips to consider when choosing an injection mold manufacturer include evaluating their portfolio and client testimonials. Look for case studies that demonstrate their problem-solving skills and adaptability. Additionally, inquire about their design and engineering processes; a manufacturer that utilizes advanced simulation tools can predict potential issues early, avoiding costly mistakes later.

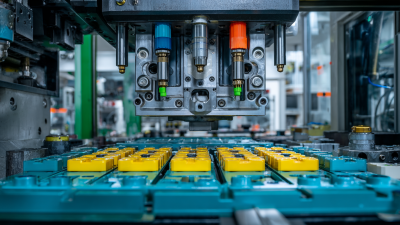

Another noteworthy project involved a consumer electronics brand that needed high-quality molds for a new smartphone model. The manufacturer employed state-of-the-art materials and techniques, allowing for efficient production and enhanced product durability. Observing such successful endeavors can provide insights into a manufacturer’s ability to deliver tailored solutions that meet specific industry demands.

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786