Injection molding mold production is a critical aspect of manufacturing that significantly influences the quality and efficiency of the final products. According to a report by the Plastic Industry Association, the injection molding market is projected to reach $305.9 billion by 2027, reflecting its importance across various sectors, including automotive, consumer goods, and healthcare. However, the production of injection molding molds is fraught with challenges, such as design complexities, material selection, and maintenance issues, which can lead to increased costs and time delays.

Understanding these common challenges is essential for manufacturers aiming to optimize their processes and enhance productivity. In this blog, we will delve into these challenges and explore the benefits of addressing them effectively to improve the overall efficiency of injection molding mold production.

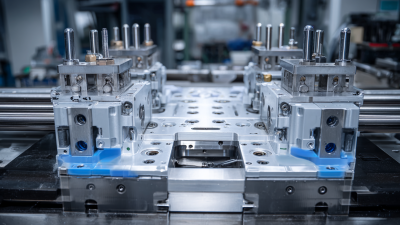

In the intricate world of injection molding mold production, the challenges in design and engineering can significantly impact operational efficiency. One key issue often faced is the complexity of the component design, which can lead to difficulties in mold fabrication. Designers must strike a balance between innovative shapes and practicality, ensuring that the mold can be efficiently produced and maintained. Any mass accumulation in the design can result in increased costs and production delays, making the initial engineering phase critical.

Another challenge arises from the selection of materials and their compatibility with the designed molds. Incorrect material choices can compromise the mold's integrity during the injection molding process, leading to defects in the final product. Continuous advancements in machine learning are being leveraged to improve the predictive accuracy of mold performance, allowing for better pre-emptive measures during the design phase. By addressing these common challenges, manufacturers can enhance production efficiencies, reduce downtime, and ultimately minimize waste in the injection molding process.

In the realm of injection molding, material selection is crucial, particularly when designing components like the inner panel of a car door. This component requires materials that not only meet structural integrity and durability standards but also facilitate the injection molding process. Research indicates that using lightweight composite materials can enhance fuel efficiency and performance in automotive applications, aligning with global trends towards sustainability. According to a report from the American Chemistry Council, lightweight materials have been shown to reduce vehicle weight by up to 20%, significantly improving fuel consumption.

In the realm of injection molding, material selection is crucial, particularly when designing components like the inner panel of a car door. This component requires materials that not only meet structural integrity and durability standards but also facilitate the injection molding process. Research indicates that using lightweight composite materials can enhance fuel efficiency and performance in automotive applications, aligning with global trends towards sustainability. According to a report from the American Chemistry Council, lightweight materials have been shown to reduce vehicle weight by up to 20%, significantly improving fuel consumption.

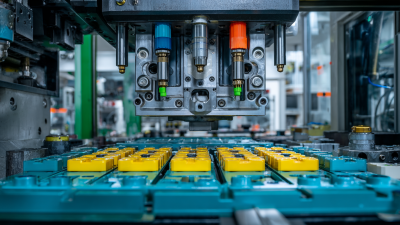

Numerical simulations conducted during the design phase of the injection mold for a car door inner panel can provide critical insights into process parameter optimization. By exploring various factors such as injection speed, temperature, and pressure, manufacturers can ensure uniform material flow and reduce defects. For instance, optimizing the cooling time and molding temperature can lead to a reduction in cycle times by approximately 15%, as highlighted in recent studies. The correct selection of materials coupled with precise process parameters can ultimately drive efficiency and quality in automotive part production.

In the realm of injection molding mold production, maintaining quality control is paramount, especially when developing components for highly competitive industries like automotive manufacturing. As the process evolves from initial pinpointing through various sample phases—A, B, C, and D samples—the importance of rigorous quality checks cannot be overstated. Each stage presents unique challenges that can significantly impact the final product, necessitating precise standards and meticulous oversight to ensure that every mold meets specifications.

Quality control during mold production involves not just monitoring material integrity and dimensional accuracy, but also adapting to the evolving needs of manufacturing processes. As automotive parts become increasingly sophisticated, with specific performance requirements, the molds must be meticulously crafted to accommodate these demands. Implementing strict standard operating procedures (SOPs) is essential to uphold quality throughout production. By fostering a culture of quality mindfulness and continuous improvement, manufacturers can navigate the complexities of mold production, reducing waste and optimizing product performance in the highly competitive automotive sector.

| Challenge | Description | Impact on Quality | Mitigation Strategies |

|---|---|---|---|

| Material Selection | Choosing the wrong material can lead to defects in the final product. | High risk of product failure. | Conduct thorough material testing and choose suppliers wisely. |

| Cooling Issues | Improper cooling rates can lead to warping or dimensional inaccuracies. | Affects the consistency and reliability of parts. | Optimize cooling channel design for even cooling. |

| Mold Design | Poor mold design can lead to difficult part ejection and defects. | Increases production time and costs. | Utilize simulation software to evaluate mold flow. |

| Maintenance | Regular maintenance is often overlooked, leading to mold wear. | Directly impacts mold longevity and production quality. | Implement a proactive maintenance schedule and inspections. |

| Operator Training | Inadequate training can result in improper handling of machines. | Increased defects and lower production efficiency. | Provide regular training sessions and upskill operators. |

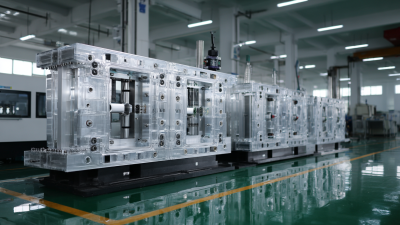

Injection molding is a prevalent manufacturing process known for its efficiency and scalability. However, cost concerns frequently challenge its implementation in mold production. One primary factor affecting cost is the initial investment needed for high-quality molds. These molds are often intricately designed and require advanced materials and technologies to ensure durability and precision, leading to significant upfront expenses.

To mitigate these costs, manufacturers should consider several strategies. First, investing in design software can help optimize mold designs, reducing material waste and production time. Additionally, utilizing simulation tools allows for virtual testing before physical production, identifying potential issues early in the process. Furthermore, collaborating with experienced mold makers can lead to better insights into cost-effective materials and manufacturing methods, ultimately resulting in a more economical production cycle without compromising quality. By addressing these cost concerns effectively, businesses can harness the full potential of injection molding while maintaining profitability.

In the fast-paced world of injection molding, handling production time constraints during mold development is a significant challenge for manufacturers. Tight deadlines often lead to rushed design and production processes, which can compromise the quality and functionality of the final product. Efficient project management and clear communication between design and production teams become essential to alleviate these pressures. By utilizing advanced scheduling tools and methodologies, businesses can maintain clarity and transparency, ensuring that each phase of mold development adheres to established timelines without sacrificing quality.

Another effective strategy to mitigate time constraints is the implementation of rapid prototyping techniques. This approach allows companies to create preliminary mold designs quickly and test them extensively before progressing to full-scale production. By identifying potential issues early on, manufacturers can make necessary adjustments without costly delays. Additionally, investing in high-quality materials and technology can streamline the manufacturing process itself, reducing lead times and enhancing overall efficiency. Embracing these strategies not only helps in managing production timelines but also positions companies to remain competitive in a demanding industry.

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786