In today's competitive manufacturing landscape, the selection of suppliers for plastic parts has become a critical factor in driving overall product quality and cost efficiency. According to a recent report by MarketsandMarkets, the global plastic parts market is projected to reach $1 trillion by 2025, underscoring the significance of strategic supplier evaluation. Companies that prioritize the assessment of quality and cost metrics can optimize their supply chains and reduce production costs by up to 20%. With the rising demand for high-performance plastic components in sectors such as automotive, aerospace, and consumer goods, understanding the key strategies for evaluating suppliers has never been more essential. This comprehensive guide aims to equip manufacturers with the tools needed to navigate this complex landscape and ensure that their choice of suppliers for plastic parts leads to sustainable business growth and innovation.

When evaluating the quality of plastic parts, understanding key quality metrics is essential, especially in light of current trends surrounding the unsustainable production of plastics and associated micro(nano)plastic pollution. The environmental impact of plastic use necessitates a careful examination of not only the physical properties of plastic parts but also their lifecycle and the implications of their degradation during use. Metrics such as tensile strength, durability, and resistance to environmental stressors are critical indicators of how a plastic part will perform over time, particularly in various recycling contexts.

Furthermore, it is important to consider how the quality of recycled plastics can influence the overall sustainability of plastic production. The introduction of a Quality Model for Recycled Plastics emphasizes the need for a holistic quality assessment, focusing on product functionality and material properties. By prioritizing these quality metrics, suppliers can not only ensure better performance but also contribute to mitigating the harmful effects of plastics in our ecosystems. As industries continue to face challenges associated with plastic waste and microplastic pollution, a rigorous evaluation framework for plastic parts is vital for supporting a more sustainable approach to plastic manufacturing and usage.

| Supplier | Material Type | Dimensional Tolerance (mm) | Surface Finish (Ra) | Defect Rate (%) | Lead Time (Days) | Cost per Unit ($) |

|---|---|---|---|---|---|---|

| Supplier A | ABS | 0.05 | 0.8 | 2.5 | 15 | 1.20 |

| Supplier B | Polycarbonate | 0.03 | 0.5 | 1.8 | 10 | 1.50 |

| Supplier C | Nylon | 0.04 | 1.0 | 3.0 | 12 | 1.10 |

| Supplier D | Polypropylene | 0.06 | 0.7 | 1.2 | 20 | 0.95 |

When evaluating the pricing models of plastic parts suppliers, understanding their cost structures is crucial for making informed decisions. A study by MarketsandMarkets reveals that the global plastic parts market is projected to reach $1 trillion by 2025, emphasizing the intense competition among suppliers. Buyers must analyze each supplier's pricing model, including fixed costs, variable costs, and any additional fees that could impact the overall expenditure.

One effective way to compare cost structures is by examining direct material costs versus operational expenses. According to a report from Grand View Research, up to 60% of the price of plastic parts can be attributed to raw materials alone, which means fluctuations in material prices can significantly affect the final cost. Buyers should be vigilant about these variables and seek suppliers who demonstrate transparency in their pricing strategies, which often leads to better negotiations and potential savings. Additionally, considering suppliers' economies of scale and production capacities can reveal opportunities for lower costs without compromising quality.

This chart compares the cost per unit and the quality scores of different suppliers. The bars represent the cost in dollars and a score of quality based on various performance metrics ranging from 1 to 10. Evaluating both dimensions helps in making informed choices when sourcing plastic parts.

When evaluating suppliers for plastic parts, assessing their reliability and reputation is crucial for ensuring quality and fostering long-term partnerships. One effective technique is to conduct thorough background checks on potential suppliers. This involves reviewing their business history, production capabilities, and the types of clients they have serviced. Engaging with existing customers can provide valuable insights into their satisfaction levels, delivery consistency, and problem-resolution processes. Online platforms that host reviews can also serve as a gauge for a supplier’s reputation in the industry.

Another important method is to analyze the supplier’s certifications and compliance with industry standards. Reliable suppliers typically possess certifications such as ISO 9001 or other relevant quality management standards, which indicate their commitment to maintaining high production standards. Furthermore, attending industry trade shows can provide an opportunity to interact directly with suppliers, allowing for firsthand assessments of their products and practices. Networking at these events often reveals reputational insights that can't be gleaned from online research alone, helping businesses make informed decisions about their partnerships.

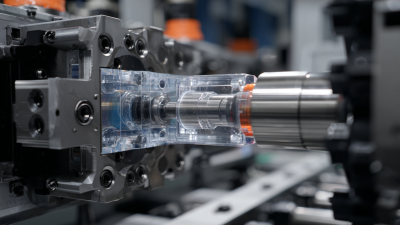

When evaluating plastic parts from various suppliers, understanding material specifications is crucial for ensuring the final product meets performance and durability requirements. According to a study by MarketsandMarkets, the global engineering plastics market is projected to reach $99.4 billion by 2025, highlighting the growing demand for high-quality materials. Key specifications to consider include tensile strength, impact resistance, and thermal stability. For instance, materials like polycarbonate and nylon are renowned for their excellent mechanical properties and are often favored in applications requiring high durability.

Another essential aspect is the compliance with industry standards such as ASTM and ISO certifications. These standards provide guidelines for material properties and testing methods, ensuring that the plastic parts can withstand various environmental conditions. A report by Grand View Research indicates that over 70% of manufacturers prioritize suppliers with comprehensive quality assurances and certifications when sourcing plastic components. Therefore, potential buyers should not only assess the cost but also evaluate the material specifications and compliance to safeguard product quality and performance in the long term.

When selecting a supplier for plastic parts, evaluating lead times and delivery performance is crucial for maintaining production schedules and meeting customer demands. Suppliers may advertise competitive prices and high-quality products, but if their lead times are inconsistent, it can disrupt the entire supply chain. It's essential to gather data on each supplier's historical performance in terms of on-time delivery rates and any patterns of delays that might affect your operations. Engaging in open communication with potential suppliers about their current capacity and any anticipated changes can also provide valuable insights into their reliability.

Moreover, understanding a supplier's logistics and fulfillment processes can further enhance your decision-making. Delays can often stem from unforeseen circumstances like supply shortages or transportation issues. Assessing each supplier's ability to navigate these challenges, including their contingency plans, will help ensure that you choose a partner who can consistently meet your needs. By focusing on lead times and delivery performance, you can mitigate risks associated with production interruptions and create a smoother workflow that ultimately benefits your business.

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786