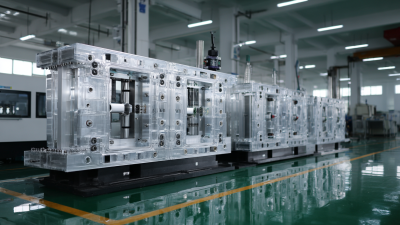

In today's competitive manufacturing landscape, optimizing the efficiency of molding machines has become a critical focus for industry leaders seeking to enhance productivity and reduce operational costs. According to a report by Grand View Research, the global injection molding machine market is projected to reach USD 12.67 billion by 2025, driven by increasing demand for lightweight and durable materials across various sectors. With advancements in technology, innovative solutions such as predictive maintenance, automation, and energy-efficient systems are essential to streamline molding processes and minimize downtime. These enhancements not only improve the overall performance of molding machines but also contribute to sustainability efforts by reducing energy consumption and waste. As manufacturers strive to meet the growing demands of consumers, adopting such innovative solutions is paramount to staying ahead in the rapidly evolving market.

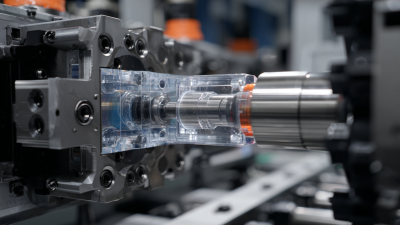

Emerging technologies are playing a pivotal role in enhancing the efficiency of molding machines, driving innovation across various manufacturing sectors. One of the most significant trends is the integration of advanced automation and robotics. These technologies not only streamline production processes but also minimize human error, resulting in higher precision and faster cycle times. As companies seek to optimize their operations, the adoption of smart robotics in injection molding is becoming increasingly vital, especially for complex applications like medical device manufacturing.

To improve molding machine efficiency, consider the following tips:

As the manufacturing industry increasingly prioritizes sustainability, molding machine efficiency is vital for companies striving to reduce waste and energy consumption. According to a recent report by the American Society of Mechanical Engineers, improving the efficiency of molding processes could decrease energy usage by up to 30%. This improvement not only slashes operational costs but also significantly reduces the carbon footprint of production. Adopting innovative technologies, such as energy-efficient motors and automated cooling systems, further enhances this potential.

In addition to energy efficiency, the implementation of sustainable practices in the molding sector can lead to a drastic reduction in material waste. The Plastics Industry Association reports that enhancing the precision of molding processes can reduce scrap rates by up to 20%. Techniques like digital twin modeling and real-time monitoring allow manufacturers to fine-tune their operations, ensuring that every component is produced with minimal excess. By integrating these cutting-edge solutions, companies can foster a more sustainable environment while positioning themselves as leaders in the industry.

| Metric | Before Implementation | After Implementation | Percentage Improvement |

|---|---|---|---|

| Energy Consumption (kWh) | 10000 | 7500 | 25% |

| Waste Generation (kg) | 500 | 300 | 40% |

| Production Efficiency (%) | 75 | 90 | 20% |

| Recycled Material Usage (%) | 10 | 30 | 200% |

In today's fast-paced manufacturing landscape, the integration of smart automation is revolutionizing molding processes, enhancing both precision and speed. By leveraging advanced technologies like AI and automation, manufacturers can significantly improve their production efficiency. For instance, innovations in injection molding machines are now utilizing deep learning for predictive control of injection velocity, ensuring that each cycle is optimized for speed and accuracy. This not only minimizes waste but also enhances the overall quality of the final product.

Moreover, the trend towards smart metrology in quality control is shifting the paradigm from reactive inspection to proactive process optimization. Predictive, data-driven methods allow manufacturers to anticipate potential issues before they arise, ensuring that products meet the highest standards. This fusion of automation and intelligent analytics is crucial in maintaining competitiveness in the global market, driving down costs while elevating product quality and customer satisfaction. Embracing these innovative solutions is essential for any manufacturing entity looking to stay ahead in an increasingly digital and automated industry.

This chart illustrates the impact of smart automation on the efficiency of molding processes. The data showcases the improvements in precision and speed due to the integration of innovative technologies in molding machines.

In the rapidly evolving landscape of manufacturing, optimizing the efficiency of molding machines is crucial for enhancing productivity and reducing costs. Leveraging data analytics, particularly through machine learning, provides innovative solutions for performance optimization. By analyzing operational data, businesses can identify patterns, predict machine failures, and make data-driven adjustments that enhance performance.

One effective approach for improving machine learning models is Bayesian Optimization for hyperparameter tuning. This method allows practitioners to systematically explore and optimize the hyperparameters of deep learning models, ensuring that they achieve the best possible performance without extensive trial and error. Implementing this technique can lead to significant enhancements in the predictive accuracy and efficiency of machine learning applications in manufacturing settings.

Tips:

The future of molding machine innovations is poised to be exciting and transformative. As industries increasingly focus on sustainability and efficiency, we can expect to see a surge in the development of energy-efficient molding machines. These next-generation machines will leverage advanced technologies such as servo motors and intelligent control systems, ensuring reduced energy consumption without sacrificing production speed or quality.

By integrating these innovations, manufacturers can not only cut costs but also reduce their environmental footprint, aligning production practices with global sustainability goals.

Additionally, the incorporation of smart technology and IoT capabilities will revolutionize how molding machines operate. Predictive maintenance, driven by real-time data analytics, will allow manufacturers to foresee potential machine failures and address them proactively. This shift towards smart manufacturing enables greater uptime, optimal performance, and a more agile response to changing market demands. As the industry adapts to these trends, we can anticipate a more interconnected and efficient landscape, setting new standards for production versatility and operational excellence in the molding sector.

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786