As the industry prepares for the 2025 China 138th Canton Fair, the focus on innovative trends in plastic injection is set to take center stage. The fair, renowned for showcasing cutting-edge technologies and products, will highlight how advancements in plastic injection molding are transforming manufacturing processes across various sectors. With an increasing demand for sustainable and efficient production methods, manufacturers are exploring new materials, techniques, and automation solutions that enhance productivity and reduce waste. From bio-based plastics to smart machinery, the innovations presented at this event are expected to redefine the landscape of plastic injection, showcasing how these developments not only meet the needs of the market but also align with global sustainability goals. As industry leaders gather to share insights and forge connections, the Canton Fair will serve as a pivotal platform for discussing the future of plastic injection in a rapidly evolving industrial environment.

As the industry prepares for the 2025 China 138th Canton Fair, the focus on innovative trends in plastic injection is set to take center stage. The fair, renowned for showcasing cutting-edge technologies and products, will highlight how advancements in plastic injection molding are transforming manufacturing processes across various sectors. With an increasing demand for sustainable and efficient production methods, manufacturers are exploring new materials, techniques, and automation solutions that enhance productivity and reduce waste. From bio-based plastics to smart machinery, the innovations presented at this event are expected to redefine the landscape of plastic injection, showcasing how these developments not only meet the needs of the market but also align with global sustainability goals. As industry leaders gather to share insights and forge connections, the Canton Fair will serve as a pivotal platform for discussing the future of plastic injection in a rapidly evolving industrial environment.

The future of plastic injection molding is set for noteworthy advancements as we approach the 2025 Canton Fair. With the injection molding market projected to grow from USD 365.22 billion in 2024 to USD 382.53 billion in 2025, and further to USD 580.44 billion by 2033, the industry's trajectory signals increasing demand and technological integration. Emerging technologies, such as automation and AI-driven processes, are reshaping the landscape, allowing manufacturers to enhance productivity and streamline operations.

As we push towards a more sustainable future, overcoming barriers to plastic recycling is essential. A proposed evaluation framework aims to boost recycling efforts, aligning with end-user preferences while fostering a circular plastics economy. This forward-thinking approach will not only minimize waste but also support the development of innovative materials and processes that meet market requirements.

**Tips:**

1. Embrace automation technologies in your molding processes to enhance efficiency and reduce operational costs.

2. Stay informed about the latest recycling innovations to ensure your practices align with sustainability goals and consumer expectations.

3. Collaborate with industry leaders to share resources and knowledge, fostering a culture of innovation in the plastic injection sector.

As the 2025 China 138th Canton Fair approaches, the focus on sustainable practices in the plastic injection molding industry is more critical than ever. Eco-friendly materials are paving the way for innovative trends, reflecting a significant shift in manufacturing that prioritizes environmental responsibility. Manufacturers are increasingly adopting biodegradable and recyclable materials, significantly reducing their ecological footprint. These new materials not only serve as alternatives to conventional plastics but also promise enhanced properties such as durability and performance.

Tips: When considering eco-friendly materials for injection molding, it’s essential to evaluate their lifecycle. Look for materials that are not only sourced sustainably but also designed for easy recycling or composting. Collaboration with suppliers who specialize in sustainable materials can provide you with insights into the best practices and innovations available.

Incorporating these sustainable practices requires careful planning and adaptation. Businesses should invest in research and development to identify the most suitable eco-friendly materials for their specific applications. Additionally, training and educating teams on the benefits and handling of these materials can lead to more successful implementations and a stronger commitment to sustainable manufacturing processes.

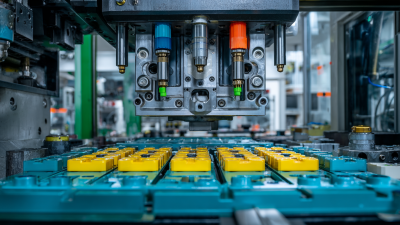

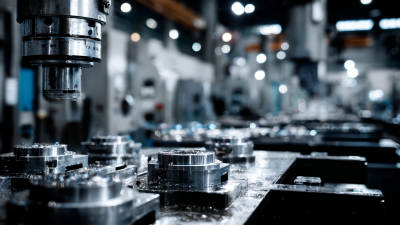

The upcoming 138th Canton Fair in China is set to showcase groundbreaking advancements in plastic injection technology, particularly emphasizing automation and robotics. According to a report by Markets and Markets, the global market for industrial automation is projected to reach $296.70 billion by 2026, growing at a CAGR of 9.2% from 2021. This growth is largely driven by the need for enhanced efficiency and precision in manufacturing processes, including plastic injection molding.

Automation and robotics are fundamentally transforming traditional plastic injection processes. By implementing automated systems, manufacturers can significantly reduce cycle times and minimize human error. A study from the International Federation of Robotics indicates that the density of industrial robots in China reached 187 units per 10,000 employees in 2020, highlighting the rapid integration of robotics in the sector. This shift not only aids in improving output quality but also aligns with the increasing demand for sustainable manufacturing practices, allowing companies to meet stringent regulations while optimizing their production lines. As firms prepare for the Canton Fair, the focus on these innovative technologies will undoubtedly reshape the future landscape of the plastic injection industry.

| Trends | Description | Expected Impact | Technology Used |

|---|---|---|---|

| Automation | Integration of automated systems to streamline production. | Increased production speed and reduced labor costs. | Robotic arms, conveyor systems. |

| Robotics | Use of robots for precision in molding processes. | Enhanced product quality and reduced defects. | AI-driven robotic systems. |

| Smart Technology | Implementation of IoT for real-time monitoring. | Improved maintenance and operational efficiency. | IoT sensors, cloud computing. |

| Sustainability | Focus on eco-friendly materials and processes. | Reduction in environmental footprint. | Biodegradable plastics, recycling technologies. |

| Data Analytics | Utilization of data-driven decisions in injection processes. | Optimized production parameters. | Big data tools, predictive analytics. |

As the 138th Canton Fair approaches in 2025, the injection molded products market is witnessing significant transformation in response to evolving consumer demands. With the market for LIM and LSR injection molding machines projected to reach $159.5 million in 2024 and $283.83 million by 2032, at a compound annual growth rate of 7.47%, the emphasis on product innovation and sustainability has never been more critical. Manufacturers are increasingly focusing on advanced materials and processes that cater to consumers' growing preferences for eco-friendly and efficient solutions.

Tips for businesses attending the Canton Fair include staying updated on the latest technological advancements in injection molding. Engaging in conversations with suppliers and industry leaders can provide insights into the most innovative practices and emerging trends. Additionally, showcasing sustainability initiatives in your products can attract environmentally-conscious consumers, creating a competitive edge in the market.

Furthermore, understanding regional market variations is essential for tailoring products to meet the specific needs of consumers in different areas. By leveraging local insights and feedback, manufacturers can enhance their product offerings and ensure that they align with changing consumer expectations. This strategic alignment is vital for navigating the competitive landscape of the injection molded products sector.

This chart illustrates the changing market trends in consumer demands for injection molded products.

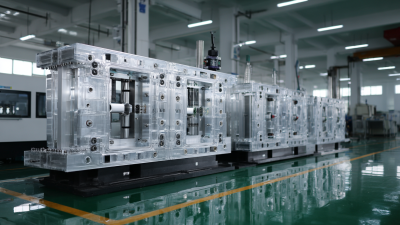

As the 138th Canton Fair approaches in 2025, innovative design techniques in plastic injection molding are set to take center stage. This year, designers and manufacturers are focusing on creating components that not only meet functional requirements but also embody aesthetic appeal and sustainability. Advanced computer-aided design (CAD) tools and simulation software are allowing designers to refine their ideas, ensuring that the molds are optimized for both production efficiency and the complexities of modern product requirements.

Sustainability has emerged as a crucial consideration in the design process. New materials and techniques, such as bioplastics and closed-loop production systems, are being integrated into the injection molding process. This shift not only reduces environmental impact but also opens up exciting possibilities for creativity in product design. As companies showcase their latest innovations at the Canton Fair, visitors can expect to see a range of plastic components that highlight cutting-edge designs and environmentally responsible practices, paving the way for the future of the industry.

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786