In today's highly competitive manufacturing landscape, optimizing your metal injection molding (MIM) process is crucial for achieving maximum efficiency and maintaining a competitive edge. As industries increasingly demand complex geometries and precise tolerances in metal components, it becomes imperative to leverage effective strategies that streamline the MIM workflow.

From material selection to process parameters and tooling considerations, each element plays a significant role in enhancing productivity and reducing lead times. This blog will explore actionable tips and best practices to refine your metal injection molding processes, ensuring that your operations not only meet but exceed industry standards. By implementing these strategies, you can maximize efficiency, minimize waste, and ultimately enhance your bottom line.

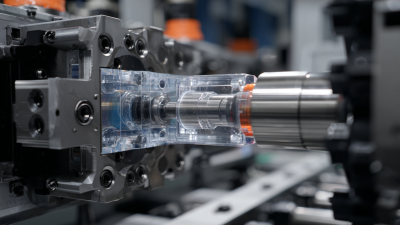

When optimizing the metal injection molding (MIM) process, identifying key variables is crucial for enhancing efficiency. One of the primary variables is the feedstock composition, which directly affects the flow characteristics and final properties of the molded parts. Fine-tuning the metal powder and binder ratio can lead to improved flowability during injection, reducing cycle times and enhancing the overall quality of the final product. Investing in high-quality feedstock materials can also minimize defects and ensure a higher density of components.

Another vital variable is the injection molding parameters, including temperature, pressure, and injection speed. Each of these factors plays a significant role in determining the consistency and repeatability of the molding process. By meticulously analyzing and adjusting these parameters, manufacturers can optimize the filling of molds and reduce the occurrence of warpage or shrinkage in finished parts. Additionally, conducting regular maintenance on equipment ensures consistent performance, allowing for reliable production runs and minimizing downtime. Understanding and manipulating these key variables not only streamlines the MIM process but also results in cost savings and superior product quality.

In the realm of metal injection molding (MIM), selecting the right materials is crucial for optimizing both efficiency and cost-effectiveness. The initial step in streamlining material selection involves a thorough understanding of the specific requirements of your application. Factors such as mechanical properties, thermal stability, and corrosion resistance must align with the intended use of the finished product. By prioritizing these criteria, manufacturers can narrow down suitable materials that not only meet performance standards but also reduce unnecessary expenses.

Additionally, it's essential to evaluate the supply chain and availability of chosen materials. Sourcing local suppliers can minimize lead times and transportation costs, significantly enhancing overall production efficiency. Collaborating with material suppliers who understand MIM processes can also lead to innovations in material formulations that provide better flow characteristics and reduce cycle times. By making informed material choices and forging strong partnerships, manufacturers can achieve a more streamlined production process, ultimately leading to improved profitability and product quality.

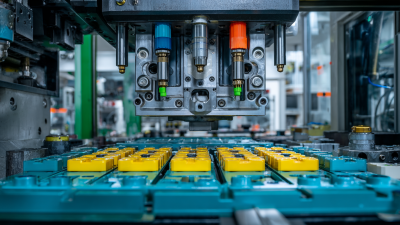

The integration of advanced technology and automation in metal injection molding (MIM) processes is revolutionizing the industry, significantly enhancing efficiency and productivity. According to a report by the International Journal of Advanced Manufacturing Technology, incorporating automated systems can reduce cycle times by up to 25%. This improvement is largely due to the seamless coordination between molding machines and auxiliary equipment, which optimizes workflow and minimizes downtime.

Additionally, the use of advanced monitoring technology, such as real-time feedback systems, empowers manufacturers to maintain tighter control over the molding process. A study by the American Foundry Society highlights that companies utilizing smart sensors and analytics can achieve a defect reduction rate of 30% or more. By accurately monitoring parameters throughout the production cycle, manufacturers can promptly identify and rectify inconsistencies, thus enhancing product quality while maximizing machine utilization.

Furthermore, adopting robotics for handling and post-processing tasks can lead to substantial labor cost savings. The Robotics Industries Association notes that businesses that implement robotic automation in their molding lines can realize a return on investment within 1 to 2 years. This shift not only streamlines operations but also frees up skilled labor for more complex tasks, ultimately driving innovation and growth in the metal injection molding sector.

| Process Stage | Technology/Automation | Benefits | Efficiency Improvement (%) |

|---|---|---|---|

| Feedstock Preparation | Automated Mixing Systems | Consistent Quality | 15% |

| Injection Molding | Robotic Arm Automation | Faster Production Times | 30% |

| Heating and Cooling | Advanced Temperature Control Systems | Improved Cycle Times | 20% |

| Post-Processing | Automated Finishing Systems | Consistent Surface Quality | 25% |

| Quality Control | Automated Inspection Systems | Reduced Defect Rates | 10% |

Quality control is a critical aspect of optimizing the metal injection molding (MIM) process, ensuring that the final products meet stringent quality standards while maximizing efficiency. According to a report from Research and Markets, the global metal injection molding market is expected to grow by 12% annually, emphasizing the necessity for consistent output quality as demand surges. Implementing effective quality control measures can not only reduce scrap rates but also enhance customer satisfaction.

One effective tip for establishing efficient quality control measures is to integrate statistical process control (SPC) into your production workflow. By monitoring key process parameters in real-time, manufacturers can identify variations before they result in defects. Studies show that industries employing SPC have reduced their product defects by up to 43%. Additionally, utilizing automated inspection technologies, such as 3D scanning, can allow for rapid assessment of each batch, streamlining the quality control process.

Another valuable tip is to focus on employee training and involvement. Empowering workers with knowledge about quality standards and best practices can significantly boost overall efficiency. A survey from the American Society for Quality found that companies that prioritize employee training in quality control report a 30% reduction in production errors. By fostering a culture of quality, manufacturers can not only enhance their output consistency but also improve their operational effectiveness.

In the quest for maximizing efficiency in metal injection molding, developing a sustainable maintenance strategy is paramount. By integrating 3D simulation and 3D printing software into the optimization process, manufacturers can significantly enhance their workflows. These technologies allow for iterative testing and refinement of designs, which helps identify potential issues during the design phase, ultimately leading to superior product quality. As such, organizations can reduce production downtime and ensure a smoother manufacturing process.

Moreover, the application of large industrial models plays a crucial role in enhancing both creativity and efficiency in design innovation. Techniques like RAG (Read-Analyze-Generate) empower companies to accelerate their product development cycles significantly. For instance, some leading organizations have leveraged these models to innovate home appliance designs rapidly, showcasing the invaluable synergy between advanced modeling techniques and market demands. The aviation sector, too, exemplifies how predictive maintenance via data analytics can preemptively address performance degradation, thereby bolstering overall operational reliability and cost-effectiveness. As industries increasingly adopt these advanced technologies, the synergy between design, efficiency, and maintenance is poised to revolutionize production methodologies across the board.

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786