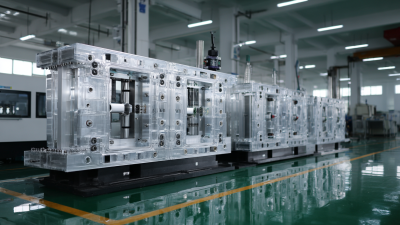

The plastic injection molding industry has seen tremendous growth, driven by an increasing demand for high-quality, efficient manufacturing processes. According to the latest industry reports, the global plastic injection molding market is expected to reach USD 342.36 billion by 2025, growing at a CAGR of 5.2%. This rise highlights the importance of optimizing production efficiency with a plastic injection machine, which is crucial for manufacturers aiming to enhance their competitiveness.

By implementing advanced techniques such as precise machine calibration, real-time data monitoring, and effective maintenance strategies, companies can significantly reduce cycle times and minimize waste. Furthermore, leveraging innovations in automation and robotics can lead to improved operational efficiency and product quality. In an era where sustainability and efficiency are paramount, understanding how to optimize the use of plastic injection machines becomes essential for achieving operational excellence and meeting market demands.

By implementing advanced techniques such as precise machine calibration, real-time data monitoring, and effective maintenance strategies, companies can significantly reduce cycle times and minimize waste. Furthermore, leveraging innovations in automation and robotics can lead to improved operational efficiency and product quality. In an era where sustainability and efficiency are paramount, understanding how to optimize the use of plastic injection machines becomes essential for achieving operational excellence and meeting market demands.

The plastic injection molding process is a widely used manufacturing technique known for its precision and efficiency in producing high-quality plastic parts.

The process begins with the melting of plastic pellets, which are then injected into a mold under high pressure. This allows for complex shapes and intricate designs to be created, making it suitable for a variety of applications, from consumer goods to automotive components.

Understanding the basics of this process is crucial for optimizing production efficiency. Key factors include the selection of the right materials, mold design, and process parameters like temperature and injection speed. By carefully controlling these variables, manufacturers can reduce cycle times, minimize waste, and enhance the overall quality of the finished product.

Additionally, regular maintenance of the injection machine and molds is essential to prevent downtime and ensure a consistent output. Overall, mastering the fundamentals of plastic injection molding can lead to significant improvements in production efficiency and cost-effectiveness.

In optimizing production efficiency with a plastic injection machine, it is essential to consider several key factors that significantly influence the injection molding process. One of the most critical factors is the choice of materials. Different plastics have varying melting points, viscosity, and cooling rates, which can directly affect cycle times and the overall quality of the molded products. Selecting the optimal material tailored to the specific application can minimize waste and ensure that the production runs smoothly.

Another vital factor is machine settings, including temperature, pressure, and injection speed. Proper calibration of these parameters can enhance consistency and reduce defects in the final product. Additionally, regular maintenance of the injection molding machine plays a significant role in ensuring efficient production. Maintenance routines should focus on components that often wear out, such as nozzles and molds, to prevent breakdowns that could lead to costly downtimes. By addressing these key factors, manufacturers can improve production efficiency and meet the growing demands of the market effectively.

Reducing cycle times in injection molding is crucial for enhancing production efficiency. One effective technique is optimizing the mold design. By ensuring that the mold has an efficient cooling system and a streamlined geometry, manufacturers can significantly reduce the time it takes for the plastic to cool and solidify.

Implementing conformal cooling channels allows for better temperature control, resulting in shorter cycle times and improved part quality.

Implementing conformal cooling channels allows for better temperature control, resulting in shorter cycle times and improved part quality.

Another approach is to adjust the injection speed and pressure. By carefully calibrating these parameters, manufacturers can ensure a faster fill time without compromising the integrity of the finished product. Additionally, employing advanced technologies such as hot runner systems can minimize waste and speed up the production process, as they allow for the continuous flow of molten plastic. These innovations not only cut down cycle times but also lead to a substantial increase in overall productivity.

Material selection is a crucial factor in optimizing production efficiency when using a plastic injection machine. The type of resin chosen directly affects the flow characteristics, cooling rates, and overall quality of the final product. Selecting materials with the right viscosity and thermal properties can lead to more consistent injection cycles, reducing cycle time and waste. For example, using a high-quality polymer that is compatible with the machine's specifications can enhance the molding process and improve the mechanical properties of the finished components.

In addition to material choice, effective material management plays a significant role in maximizing output. This involves maintaining proper inventory levels, ensuring materials are stored correctly to avoid degradation, and implementing a systematic approach to material handling. By using advanced monitoring technologies, manufacturers can track material usage and optimize replenishment strategies. This proactive management not only minimizes downtime associated with material shortages but also ensures that the production process remains streamlined and efficient, ultimately leading to higher productivity and reduced operational costs.

| Material Type | Melt Flow Index (g/10 min) | Tensile Strength (MPa) | Production Speed (units/hr) | Waste Percentage (%) |

|---|---|---|---|---|

| ABS | 15 | 40 | 300 | 2 |

| Polypropylene (PP) | 30 | 30 | 400 | 1.5 |

| High-Density Polyethylene (HDPE) | 12 | 33 | 350 | 1.8 |

| Polystyrene (PS) | 22 | 32 | 270 | 2.5 |

| Nylon (PA) | 8 | 75 | 220 | 3 |

Maintaining a plastic injection machine is crucial to optimizing production efficiency. Regular maintenance strategies can significantly enhance machine performance and extend equipment lifespan. The global oil and gas refining maintenance services market, projected to grow from $3.89 billion in 2025 to $5.1 billion by 2032 at a CAGR of 3.93%, underscores the increasing focus on proactive maintenance solutions. Companies are increasingly adopting technologies such as IoT, AI, and predictive maintenance to ensure their machinery operates at peak efficiency.

To achieve optimal maintenance, implement the following tips:

1. Schedule regular inspections and maintenance checks to identify potential issues before they lead to downtime.

2. Invest in monitoring technology, such as predictive analytics and digital twins, to gain real-time insights into machine performance, enabling faster decision-making and troubleshooting.

3. Train staff on best practices for machine operation and maintenance to promote a culture of continuous improvement and machine care.

By prioritizing these maintenance strategies, manufacturers can enhance productivity and safeguard their investment in plastic injection machinery.

This bar chart illustrates the production efficiency metrics achieved with different maintenance strategies implemented on plastic injection machines over a six-month period. The data represents the average units produced per hour under varying maintenance conditions.

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786